Accessories

Cylinder Seal Kits

Standard Cylinder Accessories

ISO Standard Cylinder Accessories

ISO-CA TYPE SINGLE EARRING

ISO-CB+PIN TYPE DOUBLE EARRING

ISO-SDB TYPE

ISO-RB TYPE

ISO Standard Cylinder Accessories - Piston-rod attachments

Piston-rod attachments

ISO-PHS TYPE FISH EYE JOINT = Rod eye

ISO-Y = Rod clevis DARC

ISO-UJ TYPE FLOAT JOINT

ISO-I

ISO-SI-TC

Mini Cylinder Accessories - Mounting bracket

Mini Cylinder Accessories = Mounting bracket

M-LB TYPE FOOT BRACKET – MS4-WR

M-FA TYPE FLANGE = Clevis foot

M-U+PIN

CYLINDER TUBE &PISTON ROD

SOON

CYLINDER TUBE &PISTON ROD

In addition to the above general sales of pneumatic cylinder aluminum tubes, our company also have some other types of aluminum tubes.

If you find the complete cylinder on the catalogue, and only need aluminum tubes, please do not hesitate to contact us, we will try our best to help you.

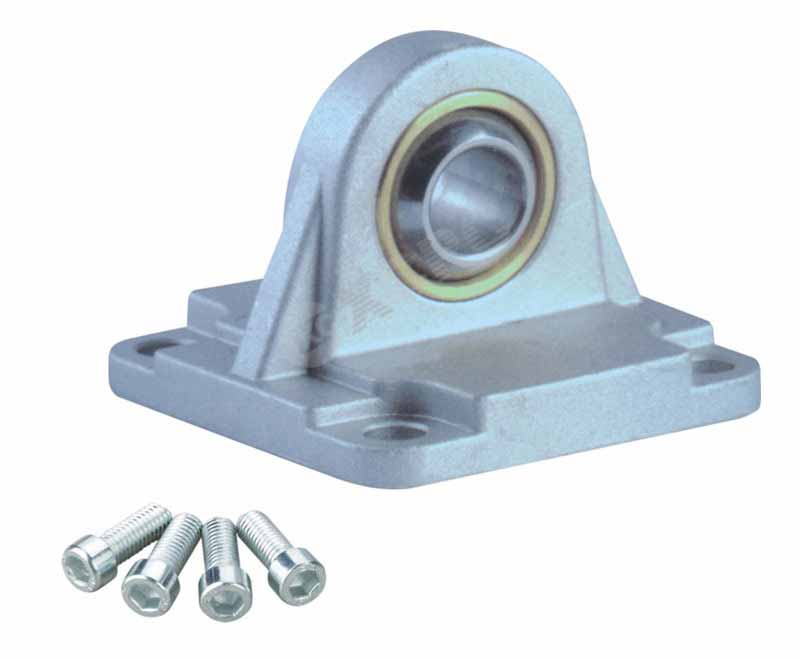

BRACKET

HAC SERIES SHOCK ABSORBERS

Pressure Gauge

Coil

solenoid coils. For direct or alternating current on the valve

Mounting position Any

Switching position indication no

Min. pick-up time 10 ms

Duty cycle 100%

Power factor cos {phi} 0.7

Coil characteristics 24 V DC: 4.5 W

42 V AC: 50/60 Hz, initial power 9.0 VA, holding power 7.0 VA

Permissible frequency fluctuations +/- 5%

Permissible voltage fluctuations +/- 10 %

Degree of protection IP65

Ambient temperature -5 °C … 40 °C

Max. tightening torque of socket 0.4 Nm

Product weight 55 g

Electrical connection 3-pin

Plug flags with connection diagram as per Festo standard for MSSD-F

Solenoid coil material Duroplast – Copper – Steel

Material of winding Copper

SAFETY VALVE FOR MINI AIR COMPRESSOR

SAFETY VALVE FOR MINI AIR COMPRESSOR

| Material | C3604 Brass | ||

| Port Size | 1/4” ~ 1/2” | ||

| Set pressure (PSI) | 175 | 205 | 250 |

| Burst pressure ±3% (PSI) ASME | 170~180 | 199~211 | 242.5~257.5 |

| Seal pressure 90% (PSI) ASME | 157.5 | 184.5 | 225 |

| Air Flow (SCFM) | 55 | 64 | 77 |

| Temp Range | -40~93.3°C | ||

Open and relieve excess pressure from equipment. And to reclose and prevent the further

release of fluid after normal conditions have been restored.

Applicable code: ASME SEC.VIII DIV.1

Each valve has been tested at 90% of set pressure for seat tightness

Reference: ASME SECTIO VIII, DIV.1 UG-136 (d)(5)

Plug DIN 43650A(Connectors)

Plug DIN 43650A(Connectors)

Distance:18mm

Form:2+1 GND

Protection Class:IP65(60529 Situation of IEC)

Working Voltage:AC250V DC300V

Nominal Current:10A

Contact Reslstance: ≤5mΩ

Max.Conductor Section:3×1.5mm²

Fixing Screw:M328

HIGH FLOW AIR BLOW GUN

Pneumatic blow gun, pistol grip, 5in nozzle, plastic, 1/4in female NPT.

TUBE CUTTER

TUBE CUTTER

|

Application

• Safe, efficient, accurate tool for cutting tubing. Specification

|

AIR BLOW GUN B30 -10.6" LENGTH TUBE

AIR BLOW GUN B30 -10.6″ LENGTH TUBE

1. Light weight and easy operation

2. Body Material: POM

3. Port Size : 1/4″ (PT,NPT,G)

4. Max. Pressure: 175 PSI (12Bar/1.2Mpa)

Air Gun

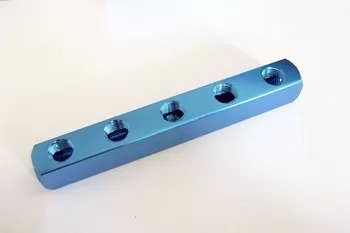

Manifold Body

Pressure switches - pressure controller

Pressure switches are present in numerous systems involved in our daily lives. From pressure switches for fire systems, pressure switches for pumping water in reservoirs to their industrial applications in various processes. Let’s understand a little more about how these components work.

The pressure switch is also known as a pressure controller, configured to detect pressure variation in a system and respond in a certain way through an electrical response. In some situations, this response given by the pressure switch occurs with an automatic system response, while there are cases where this response acts as an alert for manual action by the operator.

There are several types of pressure switches, although they all fall into one of two distinct categories: hydraulic pressure switches and pneumatic pressure switches. Hydraulic pressure switches are widely used in fire systems, swimming pools, water reservoirs, food industry, liquid fuel systems, water pump pressure switches, among others.

Pneumatic pressure switches are used in pressurized gas systems. A very common application for these components is air compressors. The pressure switch is the component responsible for detecting the pressure in the reservoir, releasing or blocking the pressurization of more air by the motor through an electrical connection.

The quality of this component is of utmost importance, not only for system operation, but for the safety of the entire process and environment, and can be decisive in fighting a fire or even preventing gas reservoirs from being subjected to pressures above their capacity. and may cause accidents of high severity.

What is an electronic pressure switch?

An electronic pressure switch has the function of converting the average pressure found in the measuring cell into a digital format. Compared to mechanical pressure switches, electronic pressure switches have a more complex operation. Despite the higher cost, these pressure switches tend to have extended durability due to the absence of moving parts, which tend to wear out more easily.

It operates as follows: The pressure measuring cell has a membrane, responsible for receiving the pressure to be measured. A circuit of resistors attached to this membrane pick up any change in pressure exerted on the membrane by changing the voltage of this system. These changes are processed by an electronic system that after processing presents the result with the execution of a command, opening or closing the contact.

Electronic pressure switches have very variable adjustment ranges, depending on the model, and a high level of precision, indispensable for some industrial applications. The reliability present in electronic pressure switches, as to its accuracy, is what guarantees the durability of an entire system, as well as equipment that depends exclusively on this component to fulfill its function.

HIGH FLOW AIR BLOWER - AIR BLOW GUN Metal air gun

HIGH FLOW AIR BLOWER – AIR BLOW GUN

Noise Reduction Nozzle Air Blow Gun (OSHA)

1. Different length nozzles for different purpose.

2. Aluminum body light weight and durable.

3. Maximum flow for easy clean-up and blow off even the heaviest shavings and chips.

4. Meets or exceeds OSHA regulations.

LOW NOISE LEVEL AIR BLOW GUN

1. Aluminum body for light weight and durable.

2. Various nozzles are available.

3. 25 bar high pressure type for superior efficiency and lower air consumption.

4. Upper or Lower Inlet port design.

5. Meets OSHA regulations.

Ball vibrator K series and GT Series Pneumatic Gear Vibrator

Ball vibrator K series

Operation pneumatic

Product applications multi-product, for bulk materials, for pipework

Type rotary, ball

Other characteristics aluminum, explosion-proof

Rotational speed Max.: 35,000 rpm (219,911.5 rad.min-1)

Min.: 7,300 rpm (45,867.3 rad.min-1)

Force Max.: 4,050 N

Min.: 130 N

DESCRIPTION

Ball vibrators, simple and good. Wide range for many applications.

Properties

• Powerful

• Rated frequency 7,300 – 35,000 rpm

• Centrifugal force 130 – 4,050 N

• Continuously variable

• Can be used up to 100°C

• HT-Version up to 150°C on request

Field of application

• Emptying of bunkers

• Screen filters

• Vibrating tables

• Preventing adhesions in piplines and silos

• Moving of goods

Construction

• Vibration – due to rotating ball running – on hardened, ground steel guides.

• Nylon plates on both sides to support the ball and as protection against dust and water.

• Housing – with – 4 mounting bores.

GT Series Pneumatic Gear Vibrator

Operation pneumatic

Type turbine

Other characteristics aluminum

pneumatic vibrators features:Only needs clean air,Work with low noise,Lubrication free,Small size, easy to install and maintain;

pneumatic turbine vibrators combines high-speed processing & eccentric torque to make a strong vibration force.pneumatic turbine vibrators inner and outer raceways of the bearings are designed so that the bearings can be easily replaced using only a pin-wrench.

The body is made from an extruded stove enamelled aluminium section and the hard coated end plates enables the vibrators to be used in the food and pharmaceutical industries.

No lubrication only clean air is required

Maximum temperature 120°C =250°F

Noise level range 60 ~75 dBA,very quiet

The GT series turbine vibrators conform to current international noise regulations under factory test conditions.

Application:

GT series vibration is produced by the central force of the positive and negative unbalanced moments in the rotor

The rotor is supported on two heavy duty, prelubricated, matched shielded ball bearings. A special long life grease ensures a long working life.

The inner and outer raceways of the bearings are designed so that the bearings can be easily replaced using only a pin-wrench.

The endplates are fitted with right- and left-hand threads and are self-locking.

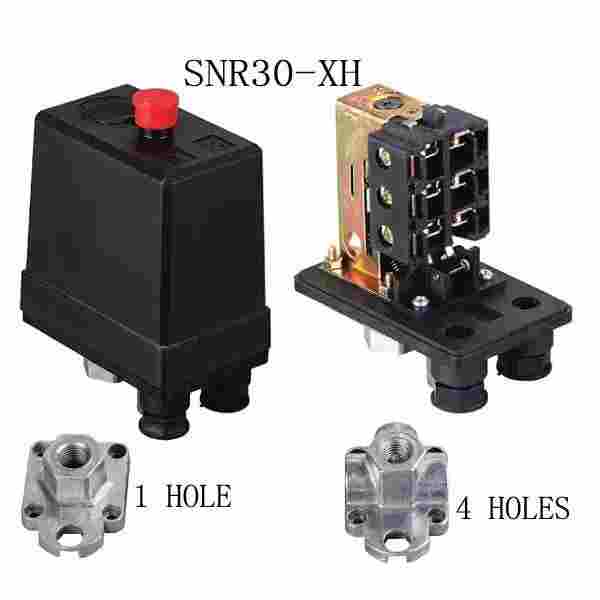

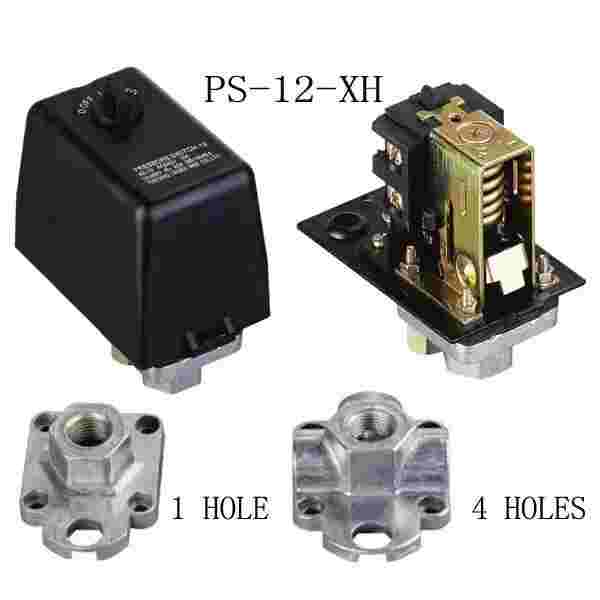

Air Compressor Pressure Switch - Automatic Air Pressure Switch

Air Compressor Pressure Switch – Automatic Air Pressure Switch

Central Pneumatic Air Compressor Pressure Switch Control Valve With 1/4″PT Thread Safety Pressure Relief Valve,Replacement Parts 90-120 PSI 4 Port 220V/380V Air Compressor Pressure

This is a nice switch for miniative air compressor.

It can help save electric power of air compressor.

Easy to install and convenient to use.

There is a red ON / OFF switch button.

automatic control. Automatic loading / unloading.

Four female air inlet holes with approx. 0.4inch / 11mm wire diameter.

Material: Metal

The color black

Voltage: 240V

Current: 16A

Maximum pressure: 6-12.5Pa

Item Size: 125 * 80 * 50mm / 4.92 * 3.15 * 1.97in

Packing list:

1 * Air compressor Switch